case studies

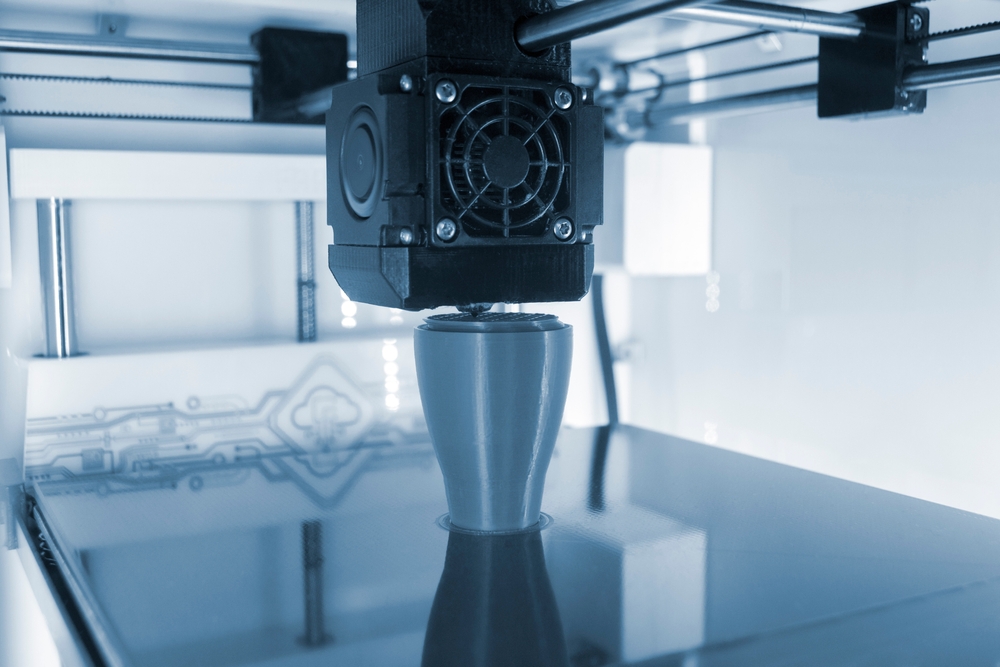

3D Printer Precision Box Build with Embedded Electronics

/)

/)

A global customer needed to commercialise a complex 3D printing system under tight budget and timeline constraints. The program demanded parallel NPI (New Product Introduction) across multiple design teams, which created coordination challenges. With no internal manufacturing capability, the entire build had to be outsourced. The customer required a partner who could take ownership of the end-to-end process while maintaining speed, cost control, and quality assurance.

FVG deployed subject matter experts in metals, electronics, wiring, and system integration directly at the customer’s R&D hub. This on-site presence accelerated decision-making and problem solving, while also ensuring alignment between design and manufacturing.

By leveraging Malaysia’s robust manufacturing ecosystem, FVG established a flexible build platform capable of evolving alongside the product design. The approach combined technical depth with adaptability, allowing design changes to be integrated without slowing down progress.

Manufacturing Process:

System Integration: Full mechanical assembly with embedded electronics, wiring, and metal structures.

Collaboration: On-site engineering support to align R&D and production scale-up.

Box Build Solution: A complete end-to-end build platform ready for commercialisation.

FVG delivered the full NPI build in just four weeks by combining DVT and PVT cycles, supported by a cross-functional team of specialists. The project achieved cost targets of USD 100K per unit, significantly below the industry benchmark of USD 200K to 800K.

Beyond immediate cost savings, the production framework was designed with foresight. The path from prototype to higher volume production was already established, giving the customer a scalable platform for future growth.

Contact us to find out more.