news

Flexi Versa Group: Delivering Reliable Plastic Injection Moulding Through Precision and a Strong Malaysian Supply Chain

/)

/)

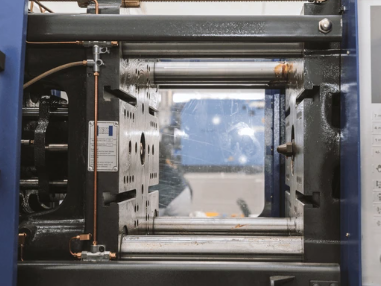

Flexi Versa Group has built a strong reputation for delivering reliable, high-precision plastic injection moulding solutions, and today our capabilities are more robust and integrated than ever. With 71 injection moulding machines ranging from 60 tons to 650 tons, we support a wide range of product requirements—from small, intricate components to large structural parts. This breadth of capacity enables us to respond quickly to customer needs, scale production efficiently, and maintain consistent quality across all volumes and complexities.

A key differentiator in our manufacturing ecosystem is our in-house tooling support, complemented by strategic partnerships with experienced local toolmakers. This hybrid approach allows Flexi Versa Group to significantly shorten tool development lead times, enhance cost competitiveness, and support faster time-to-market for new products. By working closely with trusted local partners while retaining internal tooling expertise, we maintain full control over tooling quality, timelines, and engineering changes.

Our manufacturing floor is designed for precision, repeatability, and operational efficiency. Many of our injection moulding machines are equipped with multiple core sequencers, enabling smooth and reliable operation for complex part geometries. Robotic arms and automated handling systems further enhance cycle time efficiency, minimise human error, and ensure consistent part quality—critical for industries such as medical, automotive, and industrial equipment, where reliability and traceability are essential.

Beyond standard moulding, Flexi Versa Group offers advanced processes such as overmoulding and insert moulding, allowing the integration of multiple materials, metal inserts, and enhanced functional features within a single component. To support customers requiring finished or semi-finished parts, we also provide in-house secondary processes, including spray painting, pad printing, screen printing, and ultrasonic welding. Housing these capabilities under one roof reduces handoffs, simplifies supplier management, and provides customers with greater visibility and control from raw material through to final assembly.

Our in-house tool repair, rectification, and modification capabilities further strengthen cost efficiency and production stability. Tool maintenance issues can be addressed quickly without relying on external parties, reducing downtime, extending tool life, and optimising long-term tooling costs. This capability is especially valuable during ramp-up, design iterations, or high-volume production, where responsiveness directly impacts delivery performance.

Manufacturing in Malaysia provides Flexi Versa Group and its customers with a significant strategic advantage. The country offers a mature industrial ecosystem with reliable access to raw materials, packaging, tooling, and supporting processes. This well-developed supply chain reduces lead times, lowers logistics costs, and improves agility for fast-moving global markets. Malaysia’s strong infrastructure and efficient ports—particularly in Klang and Penang—enable smooth shipping to North America, Europe, and the Asia-Pacific region.

In today’s evolving geopolitical landscape, supply chain resilience has become a critical consideration. Ongoing trade tensions and tariff uncertainties between the United States and China have led many companies to diversify manufacturing locations. Malaysia has emerged as a trusted and stable alternative. By partnering with Flexi Versa Group, customers can reduce exposure to tariff volatility and geopolitical risk, while maintaining high manufacturing standards and cost efficiency.

Malaysia also plays a key role in many “China+1” diversification strategies, offering strong technical expertise alongside competitive labour and operational costs. Compared to rising costs and increasing regulatory complexity in China, Malaysia provides a predictable and business-friendly environment that supports long-term production planning and sustainable growth.

By choosing Flexi Versa Group, customers gain more than a manufacturing supplier—they gain a strategic partner with integrated capabilities spanning tooling, moulding, secondary processes, and supply chain support. Our combination of in-house tooling expertise, local partnerships, advanced automation, and Malaysia’s industrial advantages enables us to deliver high-quality products while helping customers build resilient, cost-effective, and future-ready supply chains. In an uncertain global environment, Flexi Versa Group offers the confidence, flexibility, and reliability needed to bring products to market smoothly and sustainably.

Contact us to find out more.