news

How Geopolitics Is Shaping the Future of Medical Manufacturing and how we play a role

/)

/)

The global medical industry is undergoing one of its biggest transitions in decades. The pandemic exposed vulnerabilities across healthcare supply chains, from disrupted transportation routes to overdependence on a few major manufacturing countries. Since then, companies worldwide — especially those in the US, Europe, and Japan — have been rethinking where and how their medical products are made.

Today, the medical market isn’t just looking for capability. It wants stability, quality, and geopolitical neutrality.

And this shift has opened a unique window of opportunity for Malaysia.

A Changing World, and a New Manufacturing Landscape

In recent years, geopolitical tensions, trade restrictions, and rising operational risks in certain regions have forced multinational companies to diversify their supply chains. Large OEMs are now actively seeking manufacturing partners in countries that are:

Politically stable

Strategically located

Cost competitive

Strong in manufacturing compliance

Aligned with global medical standards like ISO 13485 and FDA expectations

Malaysia checks every box.

With its neutral foreign policy, solid infrastructure, skilled workforce, and ever-growing ecosystem of medical manufacturers, Malaysia has quietly become one of the most attractive hubs in Southeast Asia for medical device production.

Johor in particular — with its proximity to Singapore, excellent port access, and expanding industrial zones — has become a preferred landing point for global companies looking to shift production away from high-risk regions.

Why Medical Companies Are Looking at Malaysia

Several factors are driving the shift:

1. Geopolitical Neutrality

Malaysia maintains strong diplomatic relations with the US, China, the EU, Japan, and ASEAN.

For companies navigating trade tensions, that neutrality offers security and predictability — crucial for regulated medical markets.

2. Strong Regulatory Infrastructure

Malaysia has made significant progress with:

ISO 13485–compliant facilities

MDA (Medical Device Authority) regulations

Harmonisation with global standards

This regulatory maturity reassures foreign companies that quality and compliance are taken seriously.

3. Proven Manufacturing DNA

Malaysia has decades of experience in electronics, plastics, precision engineering, and automation — all essential for today’s medical devices.

The country’s workforce is known for:

Technical skill

High English proficiency

Adaptability

Experience with cleanrooms and controlled environments

4. Strategic Logistics

With major ports (Pasir Gudang, Tanjung Pelepas), proximity to Singapore, and global flight routes, Malaysia offers smooth export pathways to the US, Europe, and Asia.

Where Flexi Versa Group Fits Into This New Demand

As global companies look toward Malaysia, Flexi Versa Group stands out as one of the emerging partners ready to support the transition. Our facilities in Johor are uniquely positioned to meet the expectations of medical OEMs seeking a stable, high-quality manufacturing base.

Here’s how Flexi Versa Group plays a meaningful role in Malaysia’s rise as a medical manufacturing hub:

1. ISO 13485 Manufacturing Platform

Flexi Versa Group’s quality systems are built with medical requirements in mind — documentation control, traceability, process validation, and cleanliness.

This reduces the onboarding time for medical customers who need immediate compliance readiness.

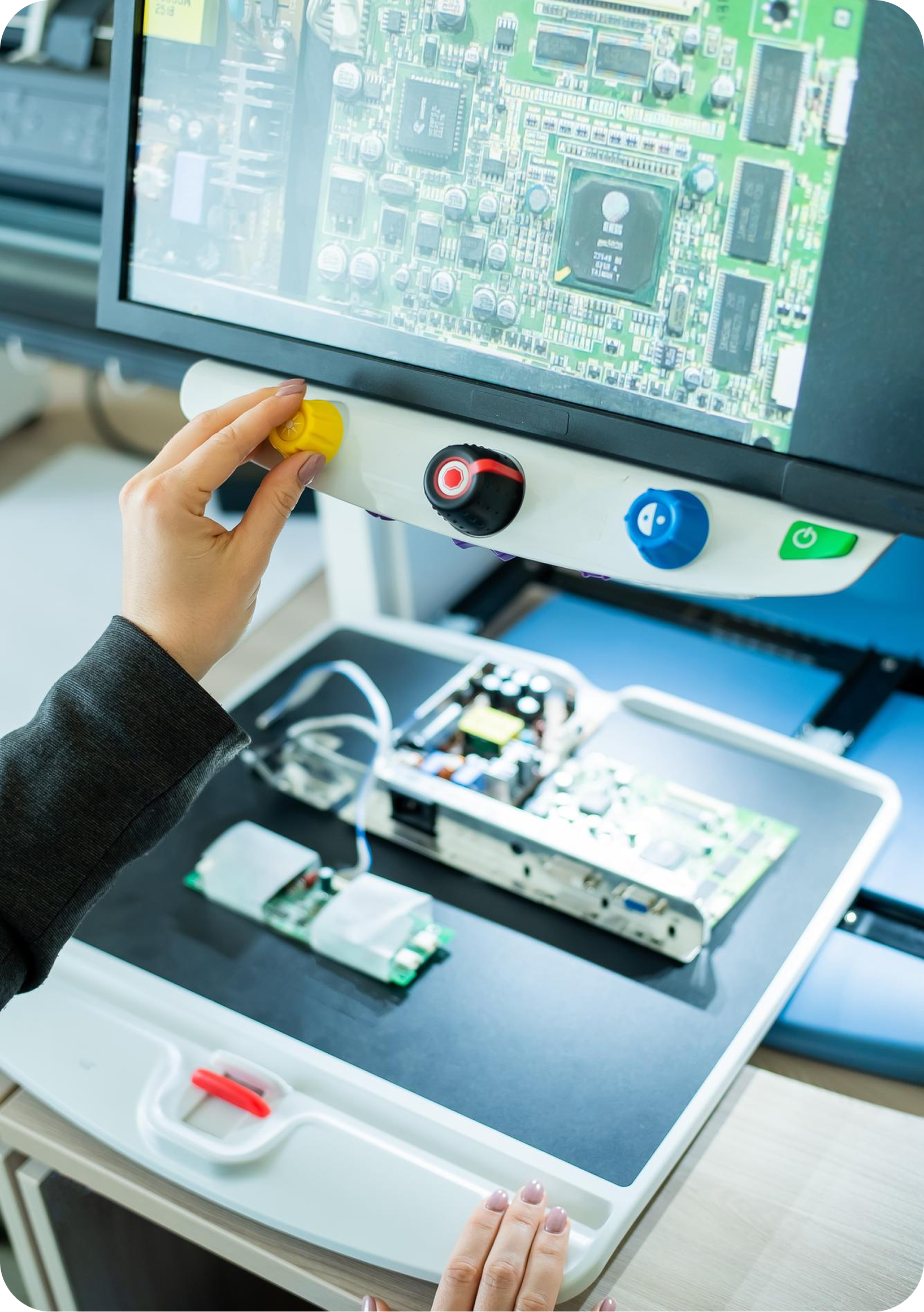

2. Class 8 Cleanroom Capabilities

From medical consumables to precision plastic components and sub-assemblies, our Class 8 cleanroom supports:

Controlled contamination levels

High process consistency

Reliable output for sensitive medical applications

It gives customers confidence that their products are handled in a space that meets global medical standards.

3. Integrated Manufacturing Services

Flexi Versa Group offers an end-to-end approach that today’s medical brands prefer:

Laser cutting for engineering plastics and foams

Screen printing for graphic interface layers

Cleanroom assembly

Box-build and integrated system assembly

Precision component production

This reduces the need for multi-supplier coordination — a major advantage for companies relocating manufacturing.

4. Strategically Located in Johor

Our proximity to:

Singapore

Port of Tanjung Pelepas (PTP)

Pasir Gudang Port

Major freight forwarders ensures smooth export flow to the US, Europe, and Asia-Pacific markets.

Customers don’t just get manufacturing capability — they get supply chain stability.

5. Agility and Engineering Support

Medical companies entering Malaysia often need:

Rapid prototyping

Local engineering troubleshooting

Small-batch validation runs before full production

Flexi Versa Group supports all these, helping customers scale faster with a trusted technical partner on the ground.

The Future: Malaysia Rising, Partnerships Strengthening

The global medical market will only continue to evolve. As companies shift operations to neutral, stable, and cost-effective countries, Malaysia stands ready — and Flexi Versa Group aims to be part of that foundation.

With ongoing expansions, capability upgrades, and a commitment to international quality, Flexi Versa is prepared not only to support today’s needs but to grow alongside the next wave of medical technology.

Malaysia is becoming a medical manufacturing destination.

Flexi Versa Group is becoming one of the reasons why.

Contact us to find out more.