news

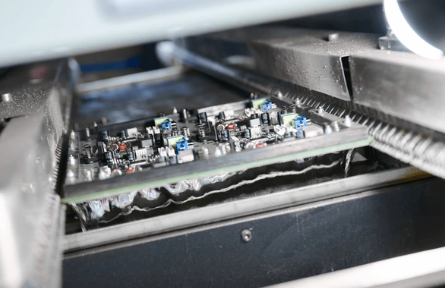

Process - Wave Soldering: Ensuring Precision and Reliability in PCB Assembly

/)

/)

What is Wave Soldering?

Wave soldering is a process where a PCB is passed over a flowing wave of molten solder, allowing the solder to attach components to the board. The board is first preheated, fluxed, and cleaned to promote proper wetting and adhesion. It is particularly effective for through-hole components, although it can also assist in mixed-technology boards (with surface-mount components pre-placed).

Common Wave Soldering Defects

Even in experienced facilities, several defects can occur if the process is not tightly controlled:

Solder Bridges

Occur when solder connects two adjacent pads unintentionally.

Often caused by excessive solder, misaligned components, or improper board design.

Cold Joints

Result from insufficient heat or poor wetting of solder on the pads and leads.

Leads to weak electrical connections and potential failures in the field.

Insufficient Wetting

When solder fails to properly coat component leads or pads.

Causes poor mechanical and electrical connections.

Component Misalignment or Tombstoning

Components may lift or tilt during soldering, creating improper contact with pads.

Often caused by uneven heating or solder surface tension issues.

Solder Balls / Spattering

Tiny solder droplets form on the board surface, often due to excessive flux, improper wave height, or high preheat temperature.

Can create short circuits or cosmetic defects.

Flux Residue or Oxidation

Residual flux or surface oxidation reduces solder quality and can affect long-term reliability.

Control Measures in Place

At advanced manufacturing facilities, strict process controls and preventive measures are applied to minimise defects:

Optimised Solder Parameters

Temperature, wave height, and conveyor speed are precisely controlled for consistent soldering.

Fluxing Control

Proper flux type and application ensure good wetting and reduce oxidation.

Preheating and Board Conditioning

Boards are preheated to reduce thermal shock and prevent cold joints or tombstoning.

Component Placement and Board Design

Proper pad sizing, spacing, and component alignment reduce the risk of bridging or misalignment.

Wave Maintenance

Regular maintenance of the solder wave, including filtration and dross removal, ensures consistent solder quality.

Inspection and Quality Checks

Automated optical inspection (AOI) and manual checks identify defects early.

Rework stations allow immediate correction of minor defects.

Training and Standard Operating Procedures (SOPs)

Operators are trained to monitor process variations and intervene before defects escalate.

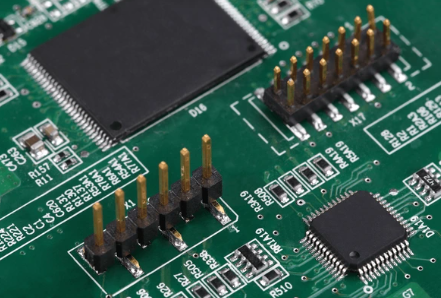

The Result: Reliable, High-Quality PCB Assembly

By combining controlled wave soldering parameters, proper board preparation, and rigorous inspection, manufacturers can minimise defects, improve first-pass yield, and deliver reliable PCBs for critical applications.

Wave soldering is more than just a production step — it is a process that demands precision, control, and continuous improvement. With the right measures in place, it remains a highly efficient and dependable method for producing high-quality electronic assemblies, whether for industrial, consumer, or medical devices.

Contact us to find out more.