news

The Story of Flexi Versa’s PCBA

/)

/)

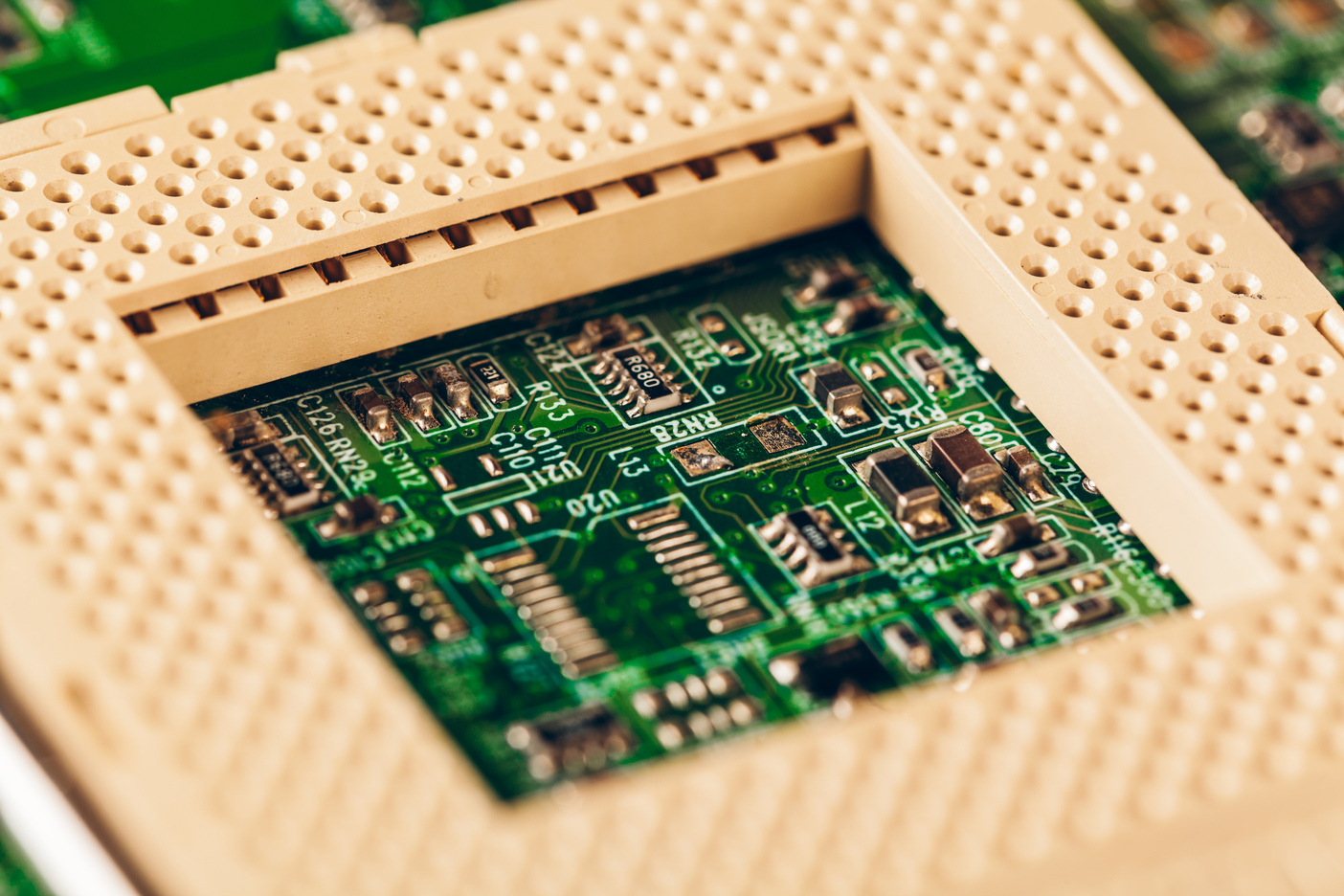

Imagine a workshop where invisible threads of electricity are carefully woven into the backbone of tomorrow’s technology. At Flexi Versa Group (FVG), ideas are transformed into reliable, high-performance electronic systems—starting from the circuit board and extending all the way to fully assembled products.

PCBA manufacturing at Flexi Versa Group goes far beyond component placement. It is built around verification, validation, and confidence at every stage of production.

No Circuit Too Simple, No Board Too Complex

On the production floor, Flexi Versa Group supports everything from straightforward single-layer PCBAs used in sensors or power modules, to highly complex multi-layer boards densely populated with micro-BGAs and fine-pitch components.

Regardless of complexity, every board is built and validated using the same disciplined approach. Design intent, electrical integrity, and long-term reliability are assessed to ensure each PCBA performs exactly as intended under real-world operating conditions.

Real-Time Intelligence on the Factory Floor

Production is governed by a Manufacturing Execution System (MES) that provides real-time visibility and full traceability. Material lots, process steps, serial numbers, and MAC addresses are tracked throughout the manufacturing lifecycle.

This digital backbone enables not only operational efficiency, but also audit-ready traceability, which is essential for industrial, medical, and other regulated markets.

Sophisticated Assembly Tools, Built for Precision

To deliver consistent quality across a wide mix of products, Flexi Versa Group deploys a comprehensive suite of advanced manufacturing technologies, including:

High-speed, high-accuracy automated placement machines

Wave soldering, selective wave soldering, and robotic soldering for mixed-technology assemblies

APS reflow ovens for precise thermal profiling

3D Automated Optical Inspection (AOI) for early defect detection

ERSA IR/PL 500 BGA rework systems for precision correction of advanced packages

This combination of automation and skilled craftsmanship ensures high yield, repeatability, and reliability—even for demanding designs.

In-Circuit Testing (ICT): Proven Capability with Flexible Options

Flexi Versa Group currently operates Agilent 3070 In-Circuit Test (ICT) systems to validate electrical integrity at the PCBA level, supporting capabilities such as:

Boundary scan testing

On-board programming

Block and discrete circuitry testing

In parallel, Flexi Versa Group remains open and flexible to exploring alternative, cost-effective ICT solutions, such as TRI-based platforms or equivalent technologies, where appropriate. This approach allows test strategies to be tailored to product complexity, volume, and customer cost objectives—without compromising test coverage or quality.

Functional Testing at PCBA Level

Functional testing is supported through:

In-house designed test fixtures

Customer-provided or transferred test platforms

These tests validate real-world performance, firmware behaviour, interfaces, and electrical functionality before PCBAs progress to higher assembly levels.

Box Build & Final Performance Acceptance Testing

Beyond PCBAs, Flexi Versa Group performs full box build functional testing, often referred to as Final Performance Acceptance Testing (FPAT). This ensures the complete product—mechanical, electrical, firmware, and system interfaces—meets defined specifications prior to shipment.

Reliability & Safety Testing for Real-World Conditions

To further ensure durability and compliance, Flexi Versa Group supports a range of reliability and safety evaluations, including:

Temperature cycling and chamber testing to assess thermal stress performance

Burn-in testing under controlled conditions to identify early-life failures

Hi-pot (high-voltage) testing to verify electrical insulation and safety compliance

These tests provide added confidence that products will perform reliably over extended lifecycles and in demanding operating environments.

Solutions for a Wide Range of Applications

Flexi Versa Group supports a broad spectrum of PCBA and system requirements, including:

High-density and fine-pitch PCBAs

Rigid and rigid-flex boards

High-reliability assemblies for medical, industrial, and automotive applications

Power PCBAs for high-current and motor control systems

Compact PCBAs for IoT, wearables, and portable devices

Conformal coating for environmental protection

Custom sensor and control modules

Looking ahead, aqueous cleaning capabilities (2025/2026) are planned to support medical and high-spec electronics requiring enhanced cleanliness standards.

Building Trust into Every Board

Flexi Versa Group’s PCBA and system assembly capabilities are not just about building electronics—they are about proving performance, ensuring safety, and delivering confidence.

By combining real-time digital oversight, skilled operators, proven test platforms, and reliability validation—while remaining flexible to adopt cost-effective testing approaches—Flexi Versa Group builds electronic foundations customers can trust, no matter how complex the innovation.

Contact us to find out more.